Welding Frame Sheet Metal Fabrication Custom Energy Storage Battery Metal Storage Cabinet Customize Server Electrical Enclosure

Overview Package Size 1270.00cm * 1300.00cm * 2400.00cm Package Gross Weight 378.000kg Product Description Welding Frame

Overview

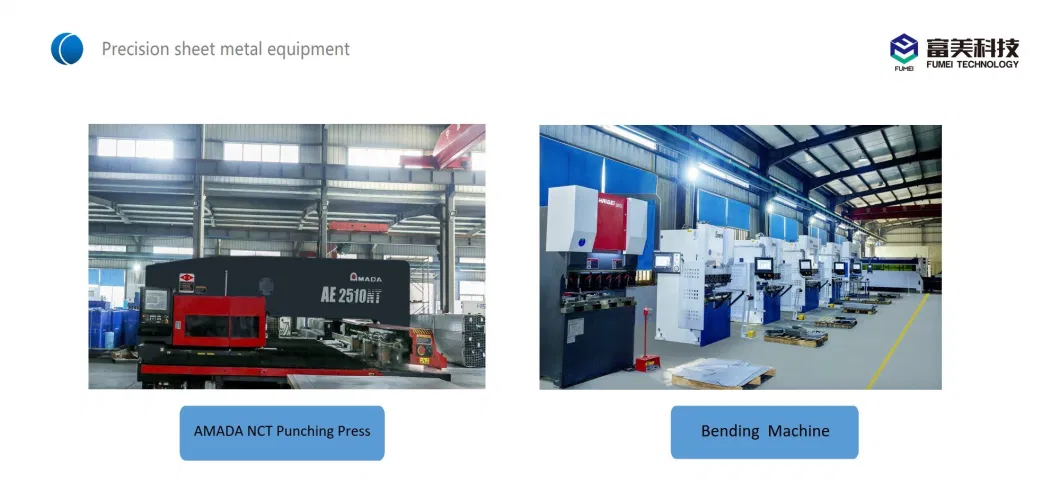

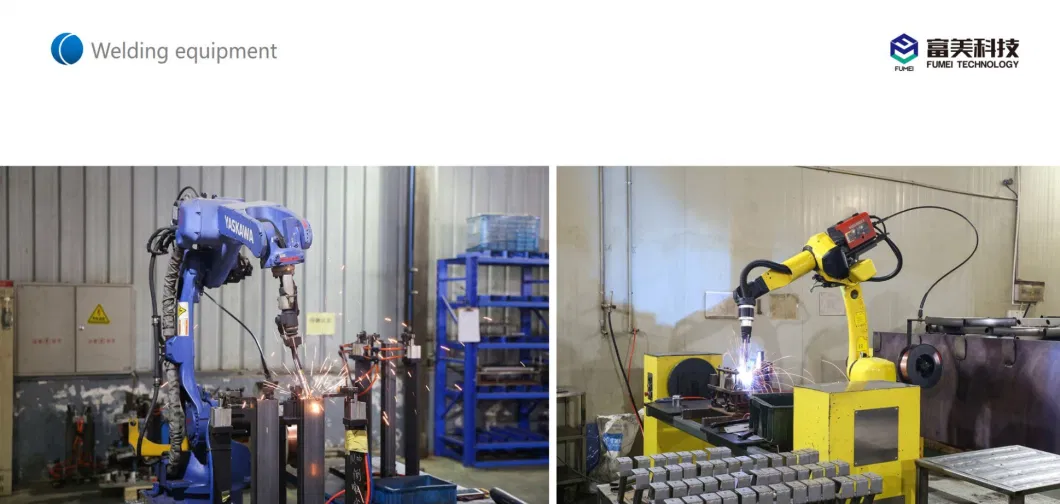

FUMEI precision sheet metal workshop has laser cutting technology, CNC punching machines, press brakes, riveting, welding, grinding, polishing, riveting and other professional equipment to ensure that your sheet metal parts are of the highest quality.

Our Sheet Metal Stamping Service Capabilities can handle the smallest to the largest parts. We are capable of producing various sizes and shapes of stamped products. Whether you need a small batch or large-volume production runs, we can accommodate your needs.

Our strict quality management procedures ensure that each fabricated part or component meets or exceeds the specifications of our clients.

We manufacture a variety of products for almost any industry and embrace all manufacturing challenges. Some of the fabricated components in our portfolio include:

Stampings | Enclosures | Card Cages | Brackets | Panels| Chassis | Housings | Racks | Boxes and Cases | Large CabinetsServices

Laser Cutting | Punching | Forming | Welding | Hardware Insertion | Assembly | Finishing

Industries Served

Automotive | Electric Vehicle | Medical | Construction | Appliances

Ningbo Fumei Technology Co., Ltd. was established in 2007 as a manufacturing-based high-tech enterprise integrating R&D, design, production, and sales. The company has a registered capital of RMB 15.5 million, owns 6 major manufacturing workshops, with a total production area of 30,000 square meters, over 500 skilled workers. The company have continuously passed ISO9001, ISO14001, and TS16949 system certification and obtain 23 patents of invention. We are a technological company with over 20 engineers in our R&D team which brings new products annually.With over 16 years of experience in precision molds and high-precision sheet metal stamping, FUMEI focuses on the two major scenes of office and home, and launches innovative ergonomic office and home products with the research and development concept of "science, comfort, and health," including a variety of products such as height adjustable desks, lifting tables, carts, and various brackets. Through ergonomically designed scientific and technological solutions, FUMEI provides users with intelligent office and home solutions, enabling them to easily achieve healthy work and comfortable living.Electric vehicles (EVs) are becoming increasingly popular as the demand for sustainable transportation solutions continues to rise. One of the biggest challenges for fleet managers in the electric vehicle industry is the storage and management of the energy generated from their EVs. From 2021, we increased the service for customers to offer energy storage cabinet and provide a safe efficient solution for this challenge. Our company implements the development strategy of high starting point, high standard, high investment and high quality, and has successively passed ISO9001, ISO14001 and TS16949 system certification. The production line is equipped with more than one hundred stamping equipment, precision machine tools, slow wire, CNC, and other mold opening equipment. The vertical integrated production equipment and delivery system include high-precision laser cutting equipment, shearing machine, bending machine, automatic welding, spraying, assembly lines, and other devices, which have flexible production capabilities and can meet the customized needs of global customers in large quantities.

FAQ for Sheet Metal Fabrication

Do you make/design your own tooling?

Yes, we have a complete tool room. We design and build our own tooling as well as utilize well-established outside tooling sources.

Do you make prototypes and help with design engineering?

Yes, we offer value engineering services & design for manufacturability assistance. Prototyping is also available.

Can you inspect complex formed parts and certify tooling?

Yes, we have a Hexagon GLOBAL SILVER Bridge Type CMM

Do you provide assembly service?

Yes, we provide mechanical assembly, welding services, finishing, packaging, etc.

Do you have finishing service?

From bead blasting to polishing, anodizing to plating, laser etching, and painting, we offer every surface treatment you need to make a great finished part.

Basic Info.

| Model NO. | FM-MCSF09 |

| Mould | Simple Single Process Dies |

| Surface Processing | Spraying |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Auto Accessories |

| Tolerances | 0.2mm |

| Customized | Customized |

| Certification | ISO9001 |

| MOQ | Flexible |

| Industry of Use | Automobile, Manufacturing Machinery, Electronics, |

| Machining Method | Cutting,Bending, Welding, Grinding, etc |

| Transport Package | Plastic Bag, Foam, Carton |

| Specification | Customized |

| Trademark | FUMEI |

| Origin | Ningbo |

| Production Capacity | 10 Thousand Pieces/Month |

Packaging & Delivery

Package Size 1270.00cm * 1300.00cm * 2400.00cm Package Gross Weight 378.000kgProduct Description

Product Description

Welding Frame Sheet Metal Fabrication Custom Energy Storage Battery Metal Storage Cabinet Customize Server Electrical Enclosure

FUMEI precision sheet metal workshop has laser cutting technology, CNC punching machines, press brakes, riveting, welding, grinding, polishing, riveting and other professional equipment to ensure that your sheet metal parts are of the highest quality.

Our Sheet Metal Stamping Service Capabilities can handle the smallest to the largest parts. We are capable of producing various sizes and shapes of stamped products. Whether you need a small batch or large-volume production runs, we can accommodate your needs.

Our strict quality management procedures ensure that each fabricated part or component meets or exceeds the specifications of our clients.

We manufacture a variety of products for almost any industry and embrace all manufacturing challenges. Some of the fabricated components in our portfolio include:

Stampings | Enclosures | Card Cages | Brackets | Panels| Chassis | Housings | Racks | Boxes and Cases | Large CabinetsServices

Laser Cutting | Punching | Forming | Welding | Hardware Insertion | Assembly | Finishing

Industries Served

Automotive | Electric Vehicle | Medical | Construction | Appliances

| Order Service: | Die/Mould Development - Prototype - Production - Inspection - Surface treatment - Packing - Shipment |

| Processing: | Punching, Bending, Stretching, Welding, Laser Cutting, Laser Drilling, Surface Treatment, etc. |

| Application Industry: | Aerospace, Construction, Medical, Defense, Transportation, Consumer Goods, Furniture, Commercial and OEM markets. |

| Our Product Specialties: | Stamping Assemblies, Brackets, Gaskets, Shims, Seals, Washers. |

| Materials: | Aluminum/Stainless Steel/ Carbon Steel/ Alloy/Copper/ Galvanized Steel Sheet |

| Dimensions: | According to Customer's Drawings or Samples |

| Surface Treatment: | Polishing, Deburring, Powder Coating |

| Delivery Time: | 15~30 Days |

| Transport Package: | PP Bag/Carton or According to Customers′ Requirement |

| Certificate: | ISO9001, ISO14001, IATF16949 |

| Production Capacity: | Metal Stamping Process: 3 Million Pcs/Month |

Stamping Equipment

Our Precision Sheet Metal Workshop is well-equipped with various professional equipment, such as high-precision laser cutting machines and CNC punching machines. It offers customized and large-scale processing services for multiple industries with short processing cycles and high precision.

| Production Workshop | Equipment | Quantity | |

| 1 | Punching Press | Punching Machine | 75 |

| 2 | BORUNTE Robot | 15 | |

| 3 | Metal Stamping | Bending Machine | 6 |

| 4 | Sheet Metal Laser Cutting Machine | 3 | |

| 5 | Tube Metal Laser Cutting Machine | 5 | |

| 6 | Automatic Tube Cutting Machine | 4 | |

| 7 | Semi Automatic Tube Cutting Machine | 2 | |

| 8 | Welding Robot | 20 | |

| 9 | AMADA NCT Punching Press | 2 | |

| 10 | Riveting Machine | 4 | |

| 11 | Surface Coating | GEMA Automatic Equipment and Guns | 2 |

| 12 | GEMA Manual Equipment and Guns | 2 | |

| 13 | Powder Coating Booths | 2 | |

| 14 | Injection Molding | Injection Molding Machine | 4 |

| 15 | Mould | Super Precision Surface Grinding Machine | 2 |

| 16 | Manual Grinding Machine | 5 | |

| 17 | Radial Drilling Machine | 3 | |

| 18 | Wire Cutting Machine | 3 | |

| 19 | Machining Center | 3 | |

| 20 | Miller Milling Machine | 2 |

Company Profile

Ningbo Fumei Technology Co., Ltd. was established in 2007 as a manufacturing-based high-tech enterprise integrating R&D, design, production, and sales. The company has a registered capital of RMB 15.5 million, owns 6 major manufacturing workshops, with a total production area of 30,000 square meters, over 500 skilled workers. The company have continuously passed ISO9001, ISO14001, and TS16949 system certification and obtain 23 patents of invention. We are a technological company with over 20 engineers in our R&D team which brings new products annually.With over 16 years of experience in precision molds and high-precision sheet metal stamping, FUMEI focuses on the two major scenes of office and home, and launches innovative ergonomic office and home products with the research and development concept of "science, comfort, and health," including a variety of products such as height adjustable desks, lifting tables, carts, and various brackets. Through ergonomically designed scientific and technological solutions, FUMEI provides users with intelligent office and home solutions, enabling them to easily achieve healthy work and comfortable living.Electric vehicles (EVs) are becoming increasingly popular as the demand for sustainable transportation solutions continues to rise. One of the biggest challenges for fleet managers in the electric vehicle industry is the storage and management of the energy generated from their EVs. From 2021, we increased the service for customers to offer energy storage cabinet and provide a safe efficient solution for this challenge. Our company implements the development strategy of high starting point, high standard, high investment and high quality, and has successively passed ISO9001, ISO14001 and TS16949 system certification. The production line is equipped with more than one hundred stamping equipment, precision machine tools, slow wire, CNC, and other mold opening equipment. The vertical integrated production equipment and delivery system include high-precision laser cutting equipment, shearing machine, bending machine, automatic welding, spraying, assembly lines, and other devices, which have flexible production capabilities and can meet the customized needs of global customers in large quantities.

Certifications

FAQ

Q1: Are you a manufacturer?A1: Yes, we are a experienced manufacturer with our own design and production lines.Q2: What's your payment term ?A2: T/T, 30% deposit when confirm the order, 70% as balance before the container loading.Q3: Can I get sample order?A3: Yes, we would like to get your sample order for testing our quality, the sample cost is paid by the customer. Q4: Are you able to customize items with design or logo?A4: Yes, OEM & ODM is available.Q5. How about MOQ?A5: Low MOQ is based on the product. We will support you as we can do.Q6: How do you ship the goods and how long it will take?A6: We normally make shipment by EMS, UPS, Fedex, TNT, DHL or AIR for small order, which usually takes about 5-12 days. And by SEA for bulk order, which usually takes about 1-2 months depend on the destination.Q7: Can I visit your company and factory in China?A7: Welcome to our company! We will pick you up or you can visit us anytime at factory address show in website.FAQ for Sheet Metal Fabrication

Do you make/design your own tooling?

Yes, we have a complete tool room. We design and build our own tooling as well as utilize well-established outside tooling sources.

Do you make prototypes and help with design engineering?

Yes, we offer value engineering services & design for manufacturability assistance. Prototyping is also available.

Can you inspect complex formed parts and certify tooling?

Yes, we have a Hexagon GLOBAL SILVER Bridge Type CMM

Do you provide assembly service?

Yes, we provide mechanical assembly, welding services, finishing, packaging, etc.

Do you have finishing service?

From bead blasting to polishing, anodizing to plating, laser etching, and painting, we offer every surface treatment you need to make a great finished part.

Send to us