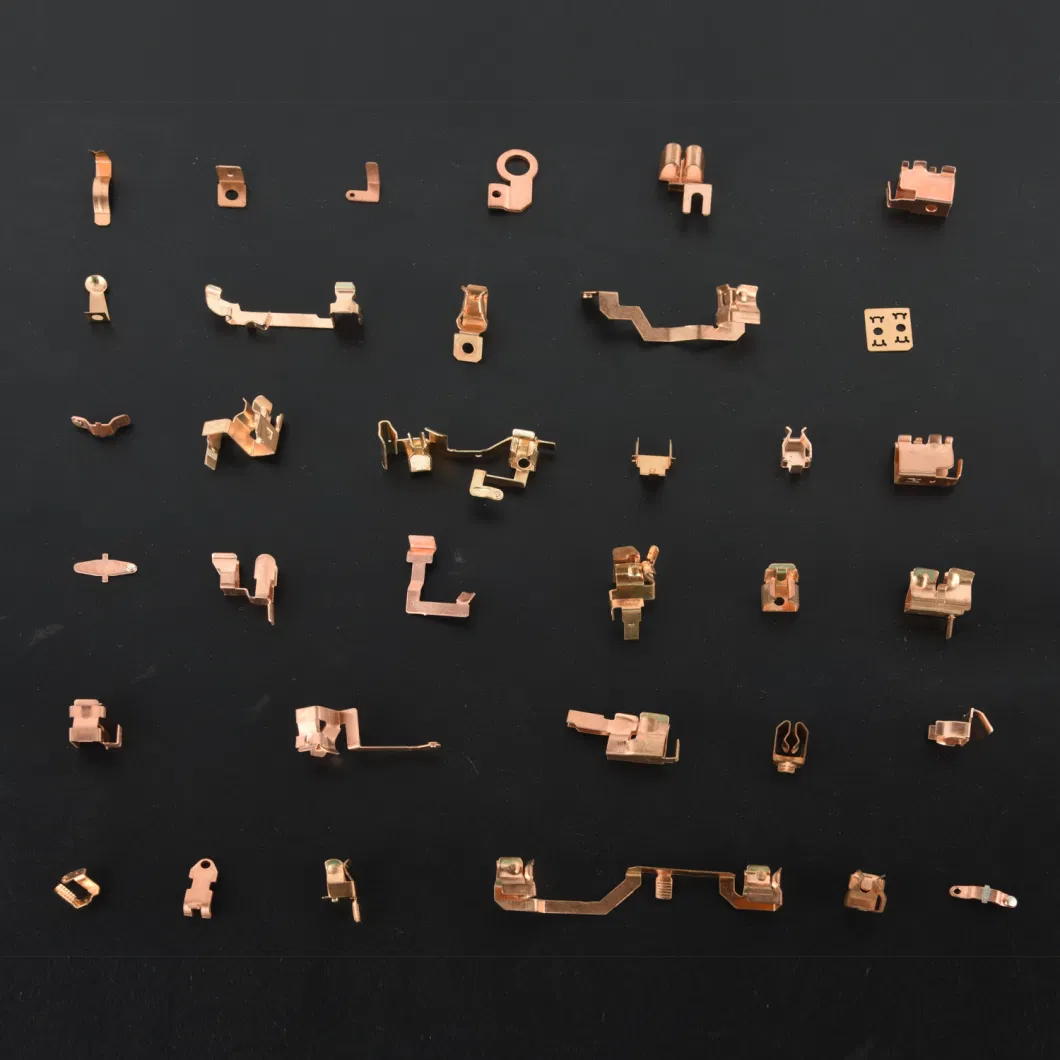

OEM High Precision Sheet Metal Stamping with Punching Welding Bending for Aluminum Electrical Accessories Components Part for Household Customized

Basic Info.

| Model NO. | SWM23 |

| Product Category | Electrical Contact |

| Application | Switch,Socket,Plug, Lamp Holder, MCB Box |

| Lead Time | 20-35 Days |

| Transport Package | as Per Your Request |

| Specification | Customized |

| Trademark | OEM |

| Origin | Ningbo |

| HS Code | 8538900000 |

| Production Capacity | 200, 0000 Per Month |

Product Description

We are a pioneer in manufacturing of precision brass turned components & assemblies for engineering electrical , electronics &plastic molding industries.Metal stamping parts we supply

1. Earth Terminal

2. Brass insert

3. Brass screw

4. Silver electrical contact

5. Springs

6. Metal Contacts For Wires Of Plug

7. Push Button Switch

8. 13A plug pin Insert

Main Material:

iron, stainless steel, copper, brass;

Key point on quality:

the final finishing status. Size tolerance & material grade;

Qualty control:

About silver electrical contact for switch, the key point is material character. Also the silver part.

For socket item, they should be in copper material, not brass material. As male pin in 4mm and 5mm will work on them. If material is not good, it will be very loose after working with 5mm male plug. About thickness, desired one is in 0.8mm, not 0.5mm, Also if the structure agrees, we should add clip to control the opening.

For saving cost and improve the quality of complete product, some Electrical stamping part are design for automatic assembling. If in this case, we should control the complete finishing from raw material, metal parts finishing, package and final handling for each connection. Any step out of order will be problem for complete finished product quality. Also the best solution is to reduce the finishing step from product design. As mechanical design is also another key factor. As even some finished step failed, it can be reformed via product structure.

Design and production time: 35-45days.