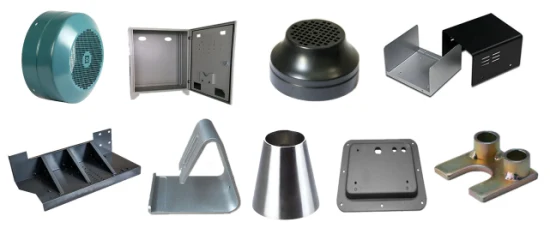

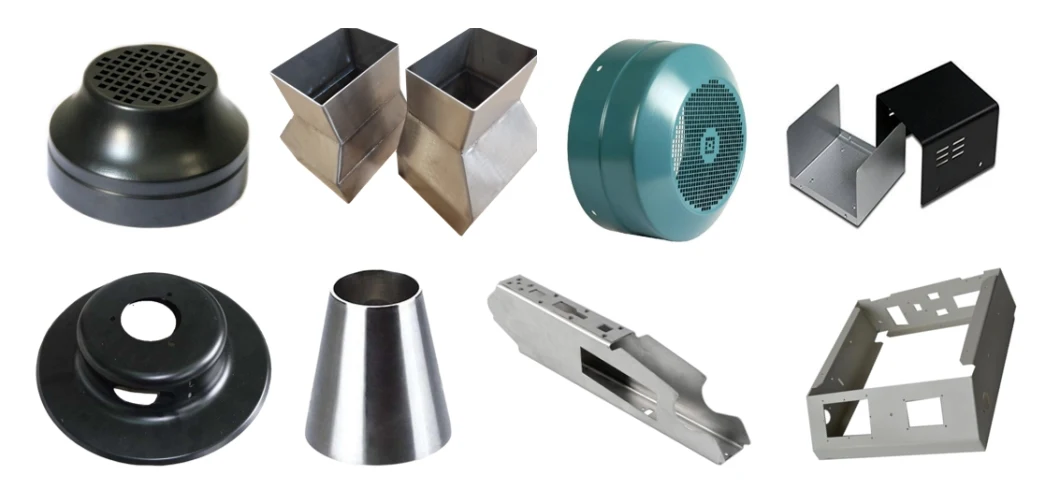

Experienced Factory Custom Sheet Metal Fabrication Aluminum 5052/5053 Part Mould Deep Drawing

Basic Info.

| Model NO. | stamping1 |

| Processing Type | Deep Drawing,Metal Spinning,Shaping Metal, |

| Material | Steel,Aluminum,Alloy Steel,Copper |

| Mould | Multistep Progressive Dies |

| Surface Processing | Polishing,Electroplating,Paint,Oxidation |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Machinery,Industry,Furniture,Metal Stamping Part |

| Tolerances | 0.1mm |

| Customized | Customized |

| Advantage | Precise High Quality Stamping Part Manufacture |

| Quality Control | Control Plan,Cpk,Flow Chart,Pfema |

| Transport Package | Bubble Bag, Box, Case, Pallet |

| Specification | as customer request |

| Trademark | OEM, ODM |

| Origin | Made in China |

| Production Capacity | 50000PCS /Month |

Packaging & Delivery

Package Size 46.00cm * 46.00cm * 12.00cm Package Gross Weight 1.900kgProduct Description

Product DescriptionOEM high precision steel,aluminum,brass, sheet meetal stamping,punching,deep drawing part manufacturer.

| Item | Specification |

| Steel Material | SUS301,SUS304,SUS430, SPCC/CRS,SPGC,SPHC/HRS,etc. |

| Aluminum Material | A1050,A1100, A1200, AL5052,AL5754, AL6061, AL6063,AL7075,etc. |

| Copper Material | C10910,C11000,C12000,C12200,C1020, C1100, C2100, C2200, C2300, C2400, C2600, etc. |

| Process | laser cutting,psma cutting,bending,punching,stamping,spinning,steel welding,aluminum welding. |

| Surface treatment | polished,wet painting,powder coating,e-coating,anodizing and other treatment as customer requirement. |

| Inspection | In-process inspection, final inspection, gauge inspection,CMM,visual inspection, NDT test; |

| Main equipment | Pneumatic press machine,Hydraulic sheet metal bending machine,Laser cutting machine, Numerical control turret punch press machine,Pipe-bending machine,Polishing machine,Welding machine,Hydraulic riveting machine,Automatic aluminum profile cutting saw,Automatic punching machine,Spinning Machine,Plate shearing machine,Lathe Machine,Drilling machine,Tapping machine. |

| Drawings format | 2D in PDF,DWG format; 3D in IGS,STP format. |

Qingdao ACES is an OEM manufacturer, mainly for casting parts, CNC machining parts and sheet metal stamping parts. We have wide experience in producing and exporting metal parts, not only for OEM parts but also have the professional team for ODM.

ACES sheet metal fabrication workshop is mainly for laser cutting, welding, stamping, bending and deep drawing parts. The materials we can do are mainly stainless steel, carbon steel, aluminum and brass.Main equipment is laser cutting machines, numerical control turret punch press machine, pipe cutting machine, hydraulic press machine 100Ton to Max 2500Ton, plate shearing machine, pipe reeling machine, robot welding.

The types of parts are electrical cabinets, covers, power cases, baffles and other industrial or furniture parts.

ACES will offer you full service from raw material to stamping finish parts including various surface treatment. Welcome to contact us if you have any concerning demands. Looking forward to your inquiry.

ACES always designs the suitable package for each part during sample development according to the part structure, qty per lot and customers requirement.

FAQ